- Home

- Quality Assurance

To show our value for high printing quality, we established a professional quality control team and a standard QC flow chart management system which provides a set of examination steps from raw materials to finished products to ensure printing quality.

quality control of raw materials

We will examine every batch of materials according to standard and clients’ demands before all raw materials enter the factory. At the same time we will also sample some printing materials for experimentation.

We will confirm materials and printing techniques in the PS plate with clients before production. After the confirmation of the first product we will start mass production.

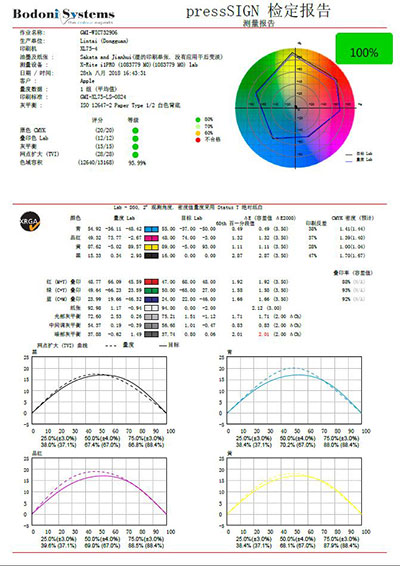

PS format quality inspectionIn the process of mass production, we will sample and examine some printings according to standards and clients’ requirements.

Continuous adhesion testHang the test plate with the sample attached on the test frame vertically with weight suspended at the lower end. Then test the ability of the adhesive tape to resist pull-off using the displacement of the sample after a certain time or complete sample-detached time.

High-temperature continuous viscosity testAttach the label to test board and put it in the facility to test label’s viscosity under high temperatures.

Color firmness test Wear testFinished product inspection

Printings sample and inspections are performed according to AQL MIL-STD-105E standards to ensure quality.